At GenCon2014 I spent almost all of my time gaming and stayed away from the thrum of the Exhibit Hall except to buy new games that I had just learned how to play. It wasn’t until around 2pm on Sunday that I really took a good look at all of the vendors, and when I came across Artisan Dice I knew I hadn’t budgeted my time (or money) correctly. Luckily, at this year’s GenCon Nika Howard and I were on a mission to find and talk to the fine folks at Artisan Dice. Following a brief interview with Charlie Brumfield we realized that we had more questions than we had time to ask, so we each bought a set of dice and then shot Charlie an e-mail of follow up questions. What follows is a combination of the two.

Where did the idea for “Artisan Dice” develop? Did you just see the need/want for a more unique dice set or was there a more utilitarian need?

God’s honest truth, it was a happy accident. I couldn’t find any fudge dice on my side of Dallas so I made some for the players in our gaming group. They got me quite inebriated and convinced me it was a good idea to launch a Kickstarter. 24 hours later I had built our website, and launched our first KS Project which funded with our very first backer then went on to raise nearly $100,000.

How do you decide what materials to use to make the dice? Once you have decided on a material, what goes into then obtaining the wood and making the dice?

I spend a large portion of my week sourcing the materials we use to make our dice, as well as discovering new materials to work with. Each material has its own unique properties so there is a significant amount of R&D that goes in to bring new materials in to our catalog. As far as obtaining our more exotic materials, we import those from all over the world. We always use sustainable sources like Eye on the Rainforest, or the African Blackwood Project, whenever possible.

In total about how many different materials ( types of wood, metal, bone etc) do you work with in making dice?

Roughly 200 at last count. Though it’s probably closer to 220 or so by now.

Are there any obstacles that you find when making the dice? For example some woods being harder to work with than others or difficulties working with natural materials? Are there any logistical restrictions on any of the types of wood that make them harder to obtain or work with? Do you have a favorite wood to work with? Do you have a least favorite?

Some of the woods and materials we use with are an absolute pain in the ass to work with. Some woods chip out during machining, others take special precautions to work with. And everyone in the shop is allergic to at least one of the species we use. Some of the most notable pains in the ass are the ones that create the biggest stench in the shop. Desert Ironwood (produces a lovely bouquet of dead possum and burnt popcorn), any of the horn, bone, or antler is just wretched to be around while we work it. And Mammoth Tusk is by far the worst stench ever produced in the shop. It rivals Skinny Minion after a bad burrito. Why do we work with all these horrid smelling materials? They make for some of the most amazing dice in the world. Else it wouldn’t be worth the effort. Desert Ironwood has a wonderful density and a golden chatoyance that you can’t find in other woods. Our buffalo horn dice polish to a piano black and feature a high contrast naturally gold toned laser engraving. And Mammoth Tusk makes for a truly beautiful piece of ancient prehistory to roll.

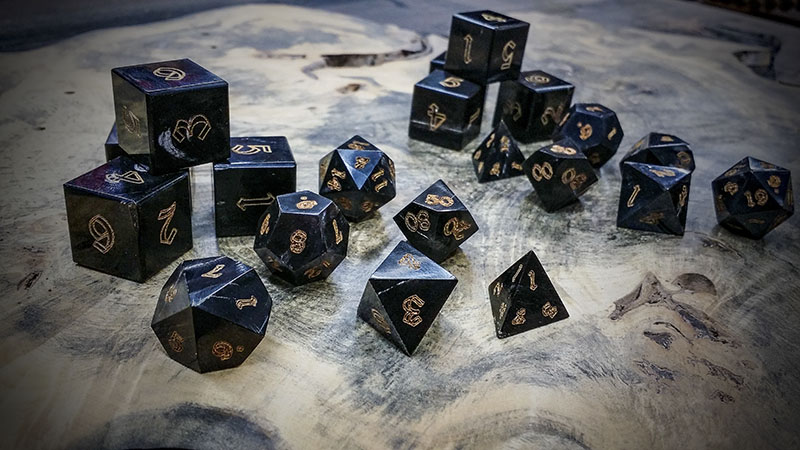

They might smell terrible when they’re being made but these buffalo horn dice are gorgeous when finished

As far as my favorite wood to work, that has to be Bois de Rose. Any of the rosewoods are a treat, but Bois de Rose is at the top of my list, for its rarity, the beautiful spicy rose scent it make while being worked, and its naturally black cherry coloration. My least favorite, we’ll that would be Black Palm Wood. Half of what we make with the particular species we have to throw away. It splinters easily while being machined and should you get those splinters in an unsuspecting digit, they go septic at the drop of a hat.

How did the idea to use the bone for dice come about? Are there any problems inherent in making bone-based dice? What made you choose alligator?

Bone dice are one of the most requested types of dice we get. We chose alligator jaw bones as we can get sustainably sourced from Louisiana. And by using the jawbones, the d6’s in our full polyhedral sets line up to show a complete section of jawbone, tooth sockets and all.

We understand that some people have taken problem issue with the idea of using bone for dice. How do you respond to people who for instance, say that mammoth belongs in a museum?

Simply put, those alligators aren’t using them anymore. They were raised for meat and leather, much like carnivorous cattle. We are simply ensuring as much of the alligator is used as possible. As to the mammoth tusk dice, no museum would touch the tusks we use to make our dice. the outer portion of the tusks are completely degraded with only the center portion of the tusk still containing usable ivory. Museums want specimen grade tusks, something we could not afford to make dice from, nor would we. The tusks we use if they were to be left alone for another thousand years or so, the entire tusk would be degraded. So we are actually preserving what we can by turning those usable portions in to piece or roll-able prehistory any gamer can put on their table to enjoy.

What sets your line of metallic dice apart from other metallic dice?

Well, for one our dice are machined from the actual metal we say they are, not cast zinc that has been plated to look like another metal. Correspondingly every type of metal dice we make has a different weight. You can feel the difference between lighter materials like aluminum and titanium, and the heavier dice like copper and steel. For those after the heaviest dice possible we have the table destroying tungsten dice. Secondly our dice are machined from solid billet, not cast.

Would you consider the product line that you have now to be complete or is there always a search for something new to add to the collection?

I’m not one of those folks than can ever leave well enough alone. So I’m always on the lookout of new and more exotic materials to make dice from.

What is the one material you’d love to be able to turn into dice but haven’t been able to yet?

Meteorite. And I’m working on fixing that.

Is there one set of dice that you’re particularly proud of, or that you think is the best you’ve made?

One of the very first sets I made was from a gentleman’s private reserve of gunstock grade english walnut. It was made entirely by hand, no use of CNC whatsoever. It has always been one of my favorites. The set was commissioned to match his collection of restored shotguns. It is a truly one of a kind set of dice.

The boxes that come with the sets are beautiful and really handy, can you talk about how you came up with the design? Is there any plan in the future to sell the boxes separately?

Our current box design is the Mk X. Remember how I said I’m never one to leave well enough alone? Well over the past 3 years I redesigned our boxes 10 separate times in an effort to make them better and better. The Mk X is a radical departure from our previous generations of boxes. For starters it’s round. It’s also design to keep the dice from rattling against one another in the box. This means dice like our Elemental line (stone) and our Dragon’s Dice (metals) won’t damage each other during shipping or storage. If you should so desire you can also remove the protective insert and store roughly 20 dice in the box. It was also design from the start with the intent to be able to offer the Mk X as a standalone purchase for those that wanted an upgraded box for the dice. As such we will be offering the Mk X dice box on our site shortly. It will be available in a large percentage of the woods we work in.

These are, understandably, somewhat expensive dice, do you have any tips or suggestions to prolong the life, color or to avoid wear on the dice?

Roll them like you stole them. We offer a life time warranty on every thing we make. That said dice in our Dragon’s Dice and Elemental Dice lines should always be stored in their protective dice cases as those dice are most dangerous to themselves due to the nature of the materials they are made from. We also highly recommend our customers do NOT use chain maile dice bags. While insanely cool, they are murder on dice in general, not just ours.

In addition to the dice it looks like you’ve made some limited run accessories (beer assistants, scotch d20’s, etc). Are you looking into expanding on a more permanent basis beyond dice?

Those are fun projects, that we may one day expand to include in our permanent line up. It always fun crafting things like our Pizza Murderer, a two handed hatchet sized pizza cutter or our Fat Bastard, one of our a more rotund fountain pens.

Is the best place to buy your dice sets on your website or are they sold in stores as well?

While our customers can always order directly from our website, we do have a number of dealers located around the world.

Artisan’s website is artisandice.com and we highly recommend you check out the dice you’ve seen in this article as well the around 200 different types they make. If you end up buying some let us know which ones you bought!

Update: It has been brought to our attention that, while everyone might agree that Artisan Dice makes good looking dice, the timelines and customer service practices of Artisan Dice leave much to be desired. Caveat Emptor. That customer clearly had a bad experience, but looking at their facebook page you’ll see several positive comments. In the interest of fairness, I am ordering a set of dice today and will up date this article as the order progresses.

8/19/2015: Prior to ordering a set of dice I emailed Artisan Dice to get an estimated timeline and received an email reply fairly quickly quoting an estimate of 10-12 weeks. This means the order should be done somewhere between 10/28/15 and 11/11/15.

8/19/2015: Ordered one polyhedral set of American Bison Horn. When ordering no shipping options were available, only free shipping, so I’m going to add a grace period for shipping of one week. This means the dice should arrive no later than 11/18/2015. Any communication I have with Artisan about this purchase will be updated as it happens.

8/24/2015: Order is awaiting materials. This update came automatically once payment had been processed, also Order placed date changed from 8/19/2015 to 8/24/2015. Unless informed otherwise I will continue to assume that the dice will arrive no later than 11/18/2015.

9/11/2015 : Order has been completed and is “now awaiting it’s custom storage case,” prior to being shipped. Looks like this is the last step. The email notes that an additional and final email will follow with the tracking number for the shipment. It certainly looks as though the dice will arrive on time, if not earlier than suggested.

10/21/2015: Received the following e-mail from Artisan Dice

Hey folks,

Just want to give everyone who is currently waiting on boxes an update, since many of your orders have been in this category for around a month now. Our box making CNC machine started malfunctioning in August due to worn out parts, and we’ve been making repairs and upgrades to it since then. After a few false starts it appears that we’re close to having it fully functional and back to making boxes, but we’re pretty backed up on these so it may take several more weeks to get enough boxes made to ship everything out. Sorry about the delay, and thanks for your patience.

Looks like I was definitely wrong about getting the dice earlier than expected. The e-mail was sent 4 weeks before my estimated time of arrival, so the question is what exactly does “several weeks” mean. I’ve emailed Artisan asking for some clarity and a rough ballpark in terms of how many weeks out my order is from being shipped.

10/27/15: Sent an e-mail asking for more specifics on the delay and received an e-mail from Artisan quoting 2-3 weeks as the expected delay. That means shipping somewhere between 11/10 and 11/17. Given this information I will either get my dice on time as quoted back in August, or a week later than expected.

11/8/15: I received an email on 11/6 letting me know that my order was complete, and had been shipped for delivery. Estimated delivery was in 1-3 days, so I’m expecting delivery on Wednesday or Thursday.

11/12/15: Dice are here, and man oh man do they look good. It took 85 days (or 12 weeks 1 day) from the day I clicked order to the day the dice arrived, which was six days earlier than I forecasted back in August. All in all I’m a very satisfied customer. E-mail communication could have been a bit more informative, but follow up e-mails were courteous and timely. Is getting dice from Artisan Dice a fast process? No, but they never claim to be fast. Given my experience, I am willing to recommend Artisan Dice to friends who are in need of some specialized dice and who have time to wait for them.

I just received my dice today after an almost 6 month wait as well. I didn’t really expect them to come in the wooden box, but was glad they did. Looks like they also included a wood D20 as well. Both unexpected aspects a nice consolation for the absolutely horrendous wait time. My dice (Second Wind Alchemist dice in Chrysocolla and Fulgar) are nice, but I wouldn’t say the colors matched those of the website photos. The colors are definitely not as varied and mottled as those on their site. The engraving and white inlay I chose are also very disappointing. The numbers are almost barely engraved, and the inlay is far from the vibrant white I chose. All in all, I don’t think I’d ever purchase from them again. I’m one of the most patient people I know, and that wait was outright ridiculous. I’m halfway tempted to write them and see what they say. I feel awful misled by their images. I’ve seen their Druid Dice in a local shop here, but I really was hoping their Second Wind dice were equally as well crafted.